Wireless technology, typically installed for a fraction of the cost of a typical hard-wired system, allows acquisition of data when wired systems are not economically feasible. Wireless technology in refinery operations is favored where redundant monitoring systems are mandated by regulatory agencies. Wireless is also considered to increase the scope of operational awareness in the control room and plant wide operations.

According to Emerson Process Management’s Gary Hawkins, while speaking at the recent AFPM Q&A and Technology Conference in New Orleans, he said, “We have seen considerable interest in automation to monitor asset health such as heat exchangers and process pumps specifically to lessen the surprises of mechanical equipment failure. The business drivers of these investments are to improve on-stream availability and the advent of wireless field devices has lowered the capital cost hurdles of adding instrumentation.”

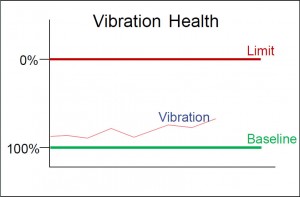

Hawkins also mentioned that refiners are also deploying wireless vibration transmitters to monitor for changing vibration patterns from pumps or motors that can provide sufficient warning to switch to a spare pump in a safe manner rather than continue to operate until a component, such as a seal, fails.

Application of wireless technology in refineries is relatively new compared to other segments of the energy industry value chain. But the past several years has seen an uptick in wireless applications as the refining industry, operating at over 90% utilization rates since late 2010, are tasked with finding ways to optimize plant productivity and reliability, improve safety and ensure regulatory compliance. For example, Western Refining’s refinery in Gallup, New Mexico installed more than 100 Honeywell wireless transmitters throughout the facility by 2011, as reported by Honeywell.

More recently, there has been a significant imperative to upgrade plant security that can be delivered by wireless systems. Advances in communications protocols enable the establishment of wireless networks to operate in the most demanding plant environments, whether in an HF alkylation unit, crude/vacuum unit, etc. The onus is on replacing, for example, outdated pneumatic devices used for valve positioning and process variable information. In other instances, wireless temperature and pressure transmitters have replaced offline temperature and pressure gauges that required manual reading. Wireless technology in such applications is based on ISA100.11a Standard, which is the Wireless Technology for Process Automation that was ratified in 2009 by the ISA100 Wireless Systems for Automation standardization group, one of the subdivisions under the International Society of Automation (ISA) organization.

Leave a Reply

You must be logged in to post a comment.