Recent opportunity crudes conferences have typically included a compendium of presentations (www.refiningcommunity.com) discussing the impact of heavy crudes on refinery operations. These well-attended symposiums usually include a wide demographic of delegates from refineries throughout the world, indicative of the level of importance being placed on these high-fouling crudes as corrosion and fouling problems are compounded with a wider diversity of seemingly “high quality” low sulfur shale based crudes with asphaltenic crudes, such as Canadian sourced diluted bitumen (“dilbit”).

Fouling and corrosion that occurs in fractionation equipment and heat exchangers when processing opportunity crudes have been discussed at length by technology suppliers schooled and experienced in these matters. Optimal processing of opportunity crudes directly impacts crude unit performance. At higher conversions (e.g., 80%), fouling in reactors is also noticeable. Opportunity crudes are, in most cases, higher acid (high TAN) crudes that predicate the need for processing assets with upgraded metallurgy and more frequent inspection programs.

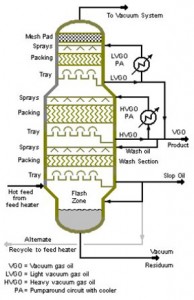

The potential margins associated with processing “opportunity crudes” need to weighed against the costs of processing these types of crudes (e.g., Arab Heavy, dilbit, etc). Another important consideration when evaluating the economics of processing opportunity crudes is the increase in hydrogen consumption. To be sure, there are many other parameters to take into consideration on an enterprise-wide level (e.g., supply and distribution network) and on a unit level (e.g., determining thickness of wash bed in crude/vacuum tower).

However, there are technical solutions that were not available until recently. For example, trying to understand the impact (fouling rate) before and after chemical treatment programs to prevent fouling in crude units processing opportunity crudes can be made more economical and effective with multiple regression analysis (MRA). Although MRA-based modeling is nothing new, its application in the mitigation of opportunity crude fouling is to provide a relationship between inlet and outlet flows (i.e., better determination of fouling rates).

Most fouling and corrosion programs are focused on overhead systems (e.g., FCC main fractionator overhead system). Significant improvements to coker main fractionator performance are also part of these technology suppliers corrosion and fouling solution set. In addition, significant discussion and exhibited demos at conferences such as the May 2016 RefComm® Galveston Refining Conference (www.refiningcommunity.com/refcomm-galveston-2016) will also focus on heat exchanger anti-foulant programs. In any event, opportunity crude focused refiners want to “engineer” fouling out of their crude processing systems. The fouling propensity of Canadian-based opportunity crudes can become even higher when combined with other types of crudes, such as Bakken LTOs. These issues are very unit specific, such that an effective fouling program at one facility may not yield the same results at another facility. Closely associated with fouling and corrosion control imperatives with opportunity crude processing are the energy efficiency improvements in crude unit operations and other processing assets, including visbreakers, cokers and ebullated bed hydrocrackers.

Leave a Reply

You must be logged in to post a comment.